Why Use Quikprotox for Vacuum Casting/Silicone Molding/Urethane Casting Services?

Nearly 80,000 European and American customers have chosen Quikprotox’s Vacuum Casting/Silicone Molding/Urethane Casting Services for the following compelling reasons:

1. Fast turnaround

Rest assured, with our 20 sets of Vacuum Casting equipment operating round the clock, swift turnarounds are guaranteed. Depending on the size and quantity of your parts, you can receive them in as early as 10 days.

2. Material and finishing flexibility

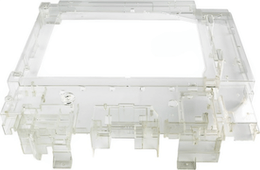

At Quikprotox, we accommodate maximum build sizes of 1500*1000mm, ensuring that your projects are executed seamlessly. Choose from our exclusive assortment of over 10 meticulously curated materials like ABS-like, PP-like, rubber, and high-temp variants, each boasting a unique set of remarkable properties. Embrace the versatility of our Vacuum Casting range, spanning from ultra-soft and flexible (Shore A) to extraordinarily robust and impact-resistant (Shore D).

Witness the magic of impeccable surface finishes, where painting, polishing, and more are at your disposal. Let us know your desired colors, and we’ll expertly paint your parts accordingly.

3. Cost-effective

Vacuum casting is the cost-effective method to create small batches of high-quality injection molding type parts for prototypes or low volume end-use parts in low stress, relatively benign environments. Additionally, our Vacuum Casting service is priced at a remarkable 70% lower than that of our European and American competitors.

What are Vacuum Casting/Silicone Molding/Urethane Casting Services?

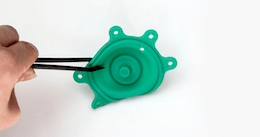

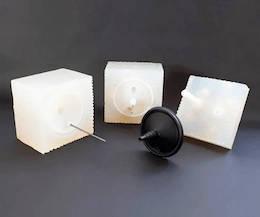

Vacuum Casting, also known as Silicone Molding or Urethane Casting, is a technology that combines silicone molds and a 3D printed master pattern to create small batches of high-quality parts in a short amount of time. Each cast part accurately replicates the color, texture, and geometry of the original master model. These parts are suitable for fit and function testing, marketing purpose, concept proofing, high quality prototypes, etc. Vacuum Casting is also widely used for customizing end-use parts. It is an ideal choice for creating impeccable prototypes and plastic parts ranging from 10 to 1000 pieces.